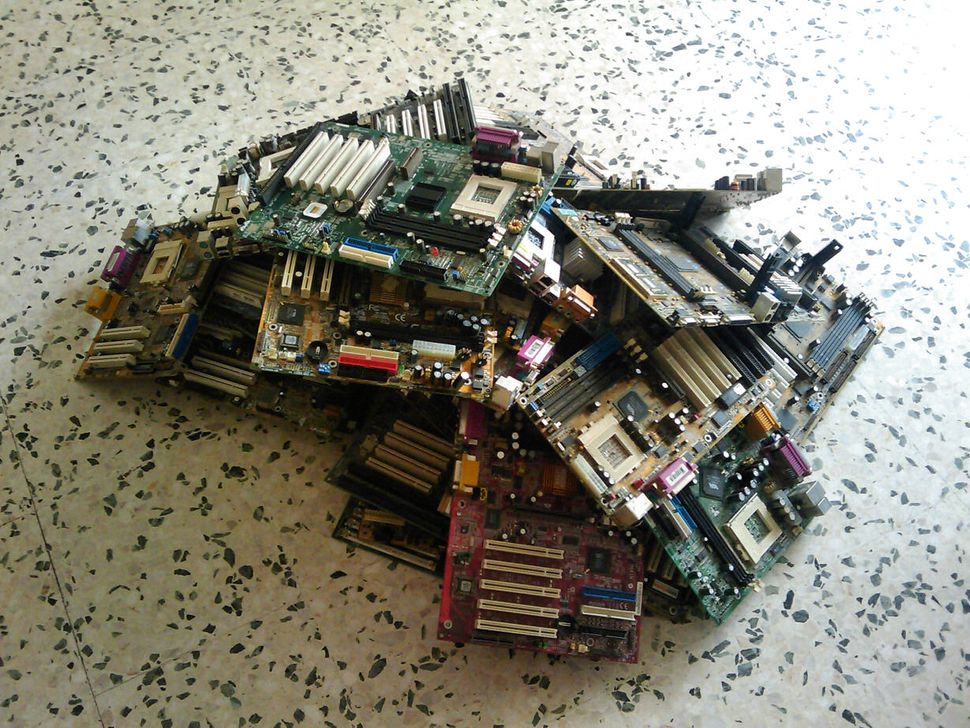

Recycling previous metals from electronic waste is very expensive and, at a large scale, often requires exorbitant amounts of power and very expensive machines to recycle efficiently. However, scientists have discovered a food byproduct, whey protein, capable of recovering gold fromelectronic waste, making the recycling process substantially more efficient than it once was. With this byproduct, the energy cost of the entire recycling process can be 50 times lower than the value of the gold extracted from electronic components. The team found they could extract around 450mg of gold from 20motherboardsusing this method.

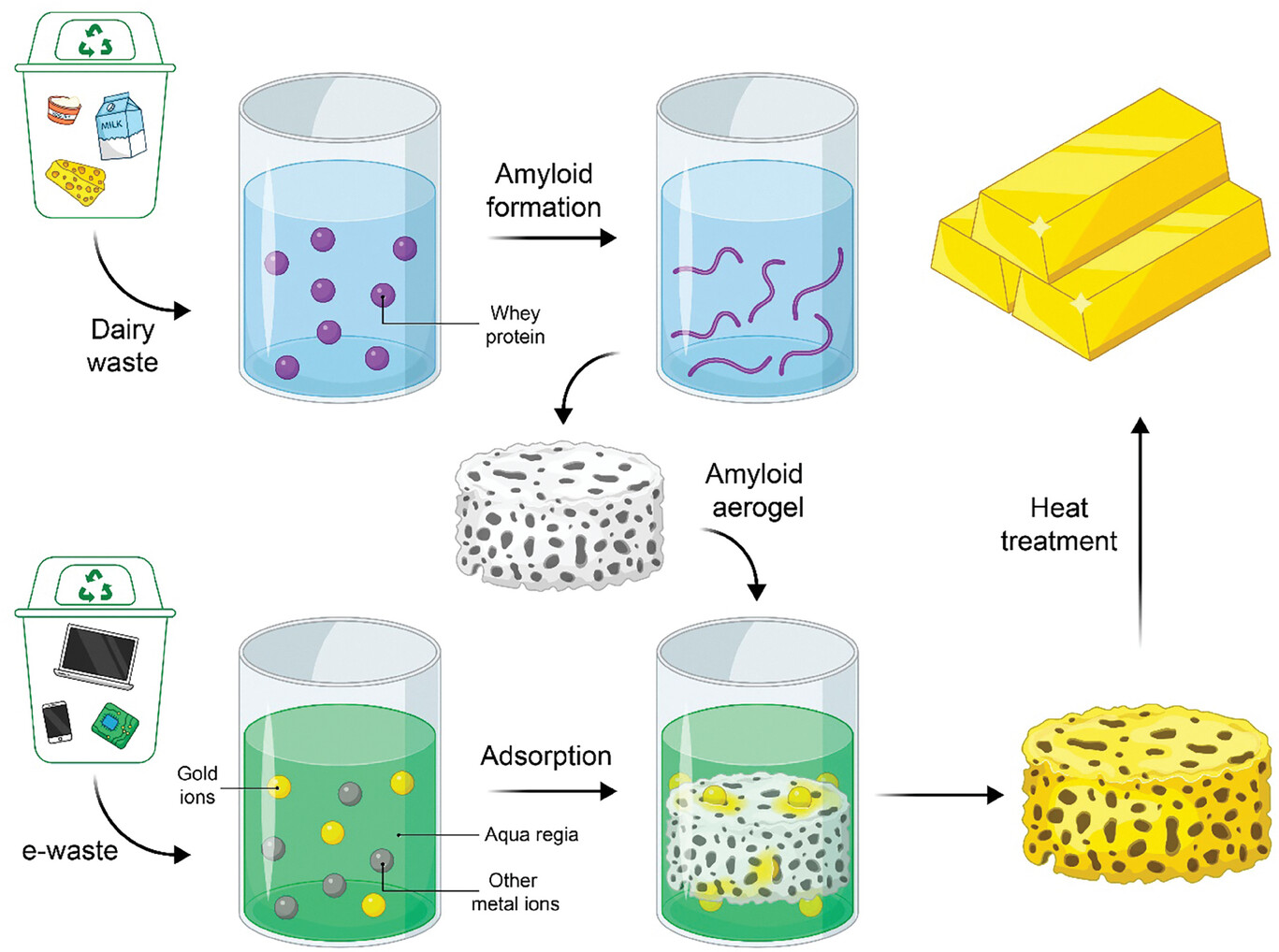

This magical organic material comes in the form of whey proteins, a byproduct of dairy. Scientist Raffaele Mezzenga from the Department of Health Sciences and Technology discovered that an organic sponge made from whey proteins is exceptionally good at extracting metals from electronic components. To make this sponge, the scientists denature whey proteins under an acidic bath and high temperatures so the substance turns into a gel. Then, the scientists dry the gel, creating a sponge out of the whey protein fibrils.

But before the sponge can be used, the electronic waste must be prepared so it can do its job. First, electronic waste is dissolved in an acid bath to ionize the metals; then, the sponge is placed in the metal ion solution. Once in the bath, the ionized metals attach to the protein sponge, like a magnet picking up metal shavings. Mezzenga and his team of scientists discovered that most metal ions can adhere to the sponge, but gold ions do so a lot more efficiently.

Finally, to extract the precious metals from the sponge, the protein sponge is heated to a temperature where the gold ions turn into flakes and can be taken off the sponge easily. In testing, Mezzenga and his team found they could extract around 450mg of gold from 20motherboardsusing this method. All the gold was melted down into a golden nugget comprised of 91% gold and 9% copper, corresponding to 22 carats.

Mezzenga’s protein sponge has a lot of potential. As previously stated, the scientist’s calculations reveal that the procurement costs of the source materials and the energy cost of the entire extraction process are 50 times lower than the value of the gold that can be recovered. If mass-produced, this technique should severely reduce the power demands of recycling plants due to the organic nature of the extraction process.

Speaking of that, Mezzanga and his colleagues reportedly want to develop the technology to sell it to customers in the electronic waste market. But there’s no due date on when that will happen. The scientists also want to investigate if they can manufacture the protein sponges out of other byproducts or waste in the food industry.

This invention could radically change the way computer waste is processed, at least waste that is rich in gold. E-waste is quickly becoming one of the biggest untapped money-making industries in the world. Right now, e-waste startups are making$85,000 per dayfrom recycling gold and copper from electronic waste. As this industry ramps up over the next few decades, recyclers will want more efficient ways to process electronic waste. Mezzanga’s sponge technology provides them with just that.

Get Tom’s Hardware’s best news and in-depth reviews, straight to your inbox.

Aaron Klotz is a contributing writer for Tom’s Hardware, covering news related to computer hardware such as CPUs, and graphics cards.