Researchers at MIT have developedand publisheda new technique called liquid metal printing “LMP” that, while limited in terms of resolution, is both fast and is said to avoid the warping and cracking seen in more traditional metal printing methods. A demonstration of this application was presented by making frames for chairs and tables in a few minutes.

The researchers used the LMP method to ensure it can print a reliable enough structure needed for different applications. Naturally, there will be fine-tuning before such 3D printers can be mass-produced and used in many industries. However, this 3D printer shows that it is reliable enough for its intended use.

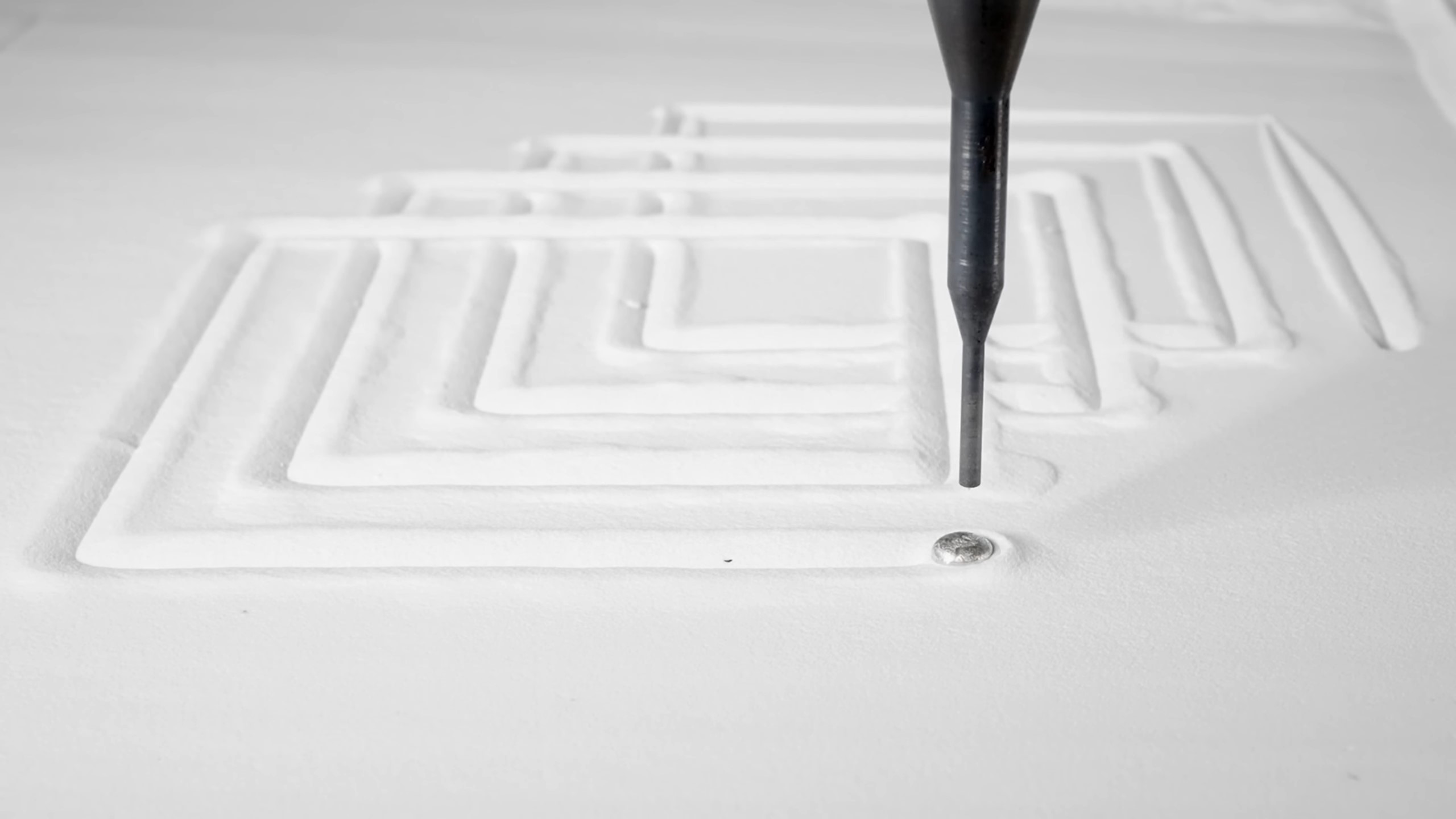

This 3D printer has a furnace that melts the aluminum, which can be scrap pieces, and stores the molten metal in a crucible, ready to be used. The machine then outlines the shape needed by the user beneath a sand-like surface made of 100-micron glass beads which absorb the heat, solidifying the metal.Throughout the process, the temperature controller maintains 700 degrees Celsius consistency until it is poured through its nozzle tip. Once printed, the melted aluminum quickly cools down to take shape, ready to be removed and processed further. Once the printed aluminum is milled and drilled as needed, it becomes ready to be assembled and used. The MIT researchers show the entire process in the video below, where the frame of a table and chair are printed.

This research was funded by automotive components maker Aisin Group, Amada Global, and a US-based furniture company Emeco. It’s not surprising to see companies from these respective fields fund such projects, which could greatly benefit their industries.

Since aluminum can be recycled multiple times, one can also use this method to make prototypes. The LMP process also allows one to print with variable thickness, providing enough durability needed for msilling and boring processe once a product is printed.

Why Aluminum?

The research paper explains that the primary purpose of this method is for the building sector, though one could apply this to many fields if it’s developed and deployed accordingly. The aerospace and automotive industries are other obvious examples, particularly when it comes to making prototypes. LMP wastes little or no aluminum material as scrap during its manufacturing process, which should add to its appeal, especially when you combine this with the strength of the end product compared to alternative methods that use things like powdered metal.

Since 3D printing now involves different materials likefoodandresinin place of filaments, it would be nice to think metal 3D printing might also make it to the home enthusiast market at some point. But since this method involves a furnace holding molten aluminum, it’s more likely that after some optimization and streamlining, it might find use in smaller-sized businesses, eventually.

Get Tom’s Hardware’s best news and in-depth reviews, straight to your inbox.

Roshan Ashraf Shaikh has been in the Indian PC hardware community since the early 2000s and has been building PCs, contributing to many Indian tech forums, & blogs. He operated Hardware BBQ for 11 years and wrote news for eTeknix & TweakTown before joining Tom’s Hardware team. Besides tech, he is interested in fighting games, movies, anime, and mechanical watches.