iFixitpublishedinformation about the iPhone 16’s repairability, giving it a ‘provisional’ repairability score, as it does for many devices. What stands out in this report is the demonstration of a unique adhesive used to seat its battery.

The adhesive can be debonded by ‘hotwiring’ a 9V battery to the device, giving a more controlled way of replacing batteries when needed. The application is enormous as it allows technicians to debond glue from any device with this application by using a small amount of current, with the iPhone 16 being the first to use such adhesives.

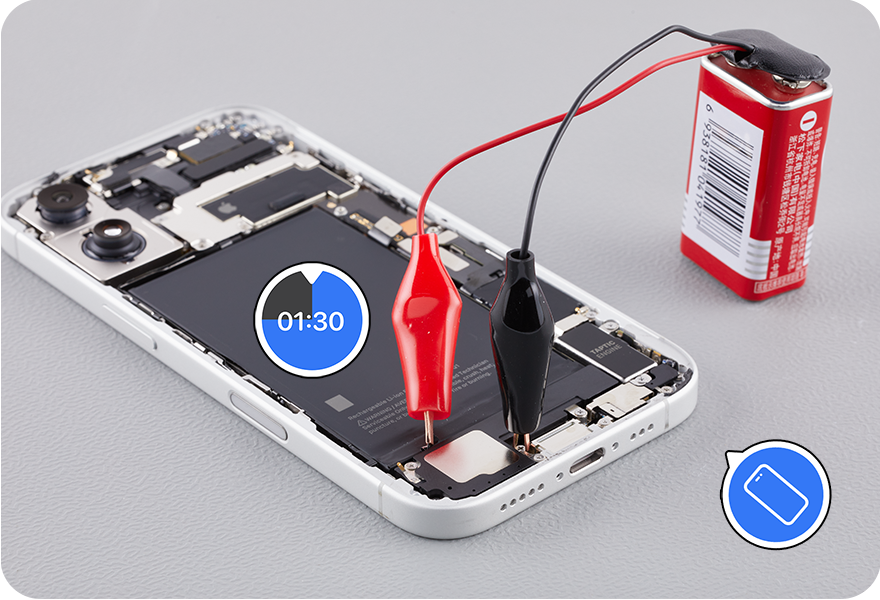

The debonding method for the battery took a minute and a half with a 9V battery, according to Apple’s repair manual. Using battery clips attached to the 9V battery, the positive clamp is secured on the silver tab on the iPhone 16’s battery, with the black connector clipped to the lower right screw on the bottom of its speaker for grounding. The result? The power agitates the applied adhesive underneath the batter, making it easily removable with no resistance.

For replacing batteries on previous models, a repair technician would use a solvent underneath the battery, which can damage other components if it overapplies or spills during this debonding method. Hence, this method increases the repair feasibility. The iPhone 16 also has specially machined ridges and rough surfaces for the glue to settle in within the frame, ensuring the possible bonding for the battery.

Battery removal using other power sources

It is mentioned in the guide that the removal time may increase with the product’s life. Though the demonstration used a 9V battery, the guide also mentions using 30V and above for faster removal and DC power supplies. iFixit did so using itsportable FixHub Power Station. Since the device was brand new and hence the applied adhesive- it took 60 seconds to debond at 12 volts with no force required. Though the process eliminates the need to use solvent for debonding, iFixit and Apple recommend using isopropyl alcohol to clean the remaining adhesive.

iFixit also spotted a research paper that explains the mechanism of this adhesive in detail. The new electrically dependable adhesive was critical for recycling, repairability, and reuse of electrical components, but making it work in real conditions was challenging. Several debonding methods were proposed over the years; however, no experiment using various materials worked until an ionically conductive material showed a good level of success. Eventually, a method was devised where electrodes could be used to make an electrochemical reaction to agitate the applied adhesive.

Using adhesive on devices like smartphones, tablets, and notebooks is very common. However, debond glue passes a low-volt battery and speeds up battery replacement while not affecting other components in the device. This would also require these types of adhesives to be readily available in the market, as the new batteries will need to be secure using the same method.

Get Tom’s Hardware’s best news and in-depth reviews, straight to your inbox.

Changing the binding material for batteries has improved over time. Most recently, research published last year showed that changing the binding material increased the battery life by up to 10%. We may see such electrically debonding adhesive widely available for different applications with different levels of strength needed for varying electronics and components.

Roshan Ashraf Shaikh has been in the Indian PC hardware community since the early 2000s and has been building PCs, contributing to many Indian tech forums, & blogs. He operated Hardware BBQ for 11 years and wrote news for eTeknix & TweakTown before joining Tom’s Hardware team. Besides tech, he is interested in fighting games, movies, anime, and mechanical watches.