Withdozens of fabs being built in Chinaandcoming online over the next few years, China is poised to expand its chipmaking capacities dramatically. Most of these fabs will produce chips using mature process technologies, enabling China to flood the chip market on these nodes. Meanwhile, experts from market research companyTrendForcewarn that this could lead to an oversupply of capacity, making foundries cut their quotes, and some may go bankrupt.

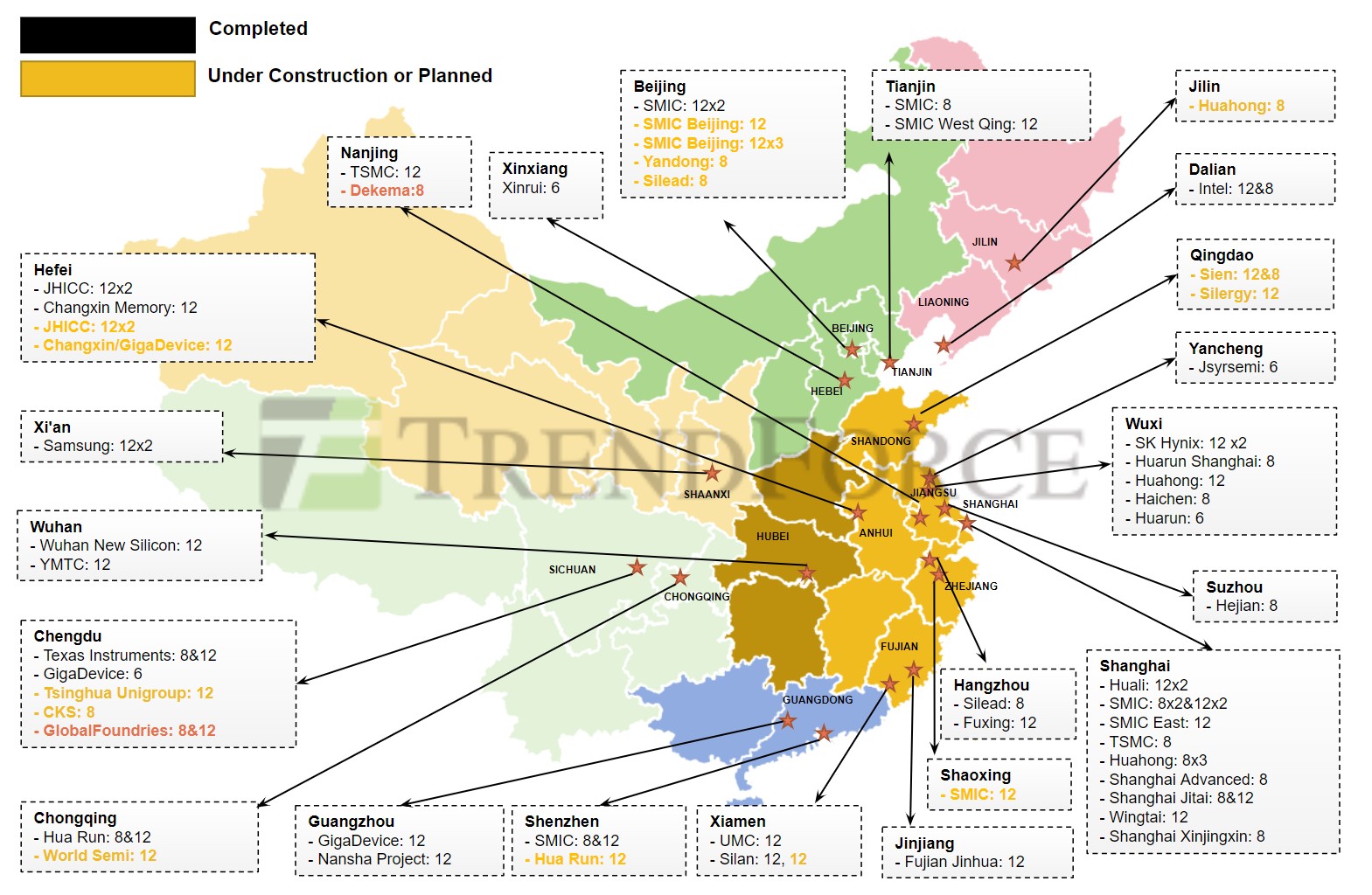

China currently has 44 wafer fabs, excluding seven inactive ones. Among these, 25 are 300-mm fabs, five process 200-mm wafers, and four process 150-mm wafers, according to TrendForce. By the end of 2024, companies like SMIC, HuaHong, Nexchip, CXMT, and Silan aim to add ten more wafer fabs to this list, comprising nine 300-mm fabs and one 200-mm facility. There are 23 more fabs under construction, including 15 300-mm and eight 200-mm facilities, bringing the total new wafer fabs to 32, and all of them are expected to come online in the coming years.

These new and upcoming fabs focus primarily on mature process technologies, specifically 28nm and thicker. To build those fabs, Chinese companies acquired hundreds of lithography tools from ASML, and importing lithography equipment from the Netherlands saw a 1050% surge in 2023. This indicates a concerted effort by China to ramp up its chip manufacturing capabilities, particularly in mature technologies that are used to build chips for a wide range of applications, including consumer electronics and Internet-of-Things.

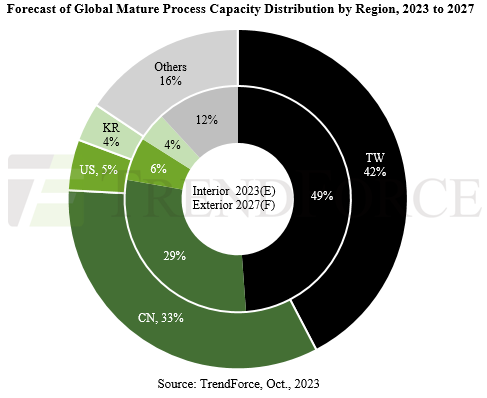

TrendForce forecasts a global ratio of mature (greater than 28nm) to advanced (less than 16nm) semiconductor processes at around 7:3 from 2023 to 2027. With China’s capacity in mature processes expected to grow from 29% to 33% by 2027, there’s potential for a significant influx of these chips into the global market, potentially triggering a price war. This growth also indicates a trend towards increased localization in sectors like display driver IC (DDIC), CIS/ISP, and power management ICs (PMICs), posing risks of client erosion (i.e., smaller fabless chip designers go bankrupt) and pricing pressures for smaller foundries with similar processes.

Get Tom’s Hardware’s best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.