The Lawrence Livermore National Laboratory isworkingon a petawatt-class thulium laser that is said to be 10 times more efficient than the CO2 lasers used in EUV tools and could replace CO2 lasers in lithography systems many years down the road.

The LLNL-led initiative will evaluate theBig Aperture Thulium (BAT) laser technologyto enhance EUV source efficiency by approximately tenfold compared to the current industry-standard CO2 lasers. This advancement could pave the way for a new generation of ‘beyond EUV’ lithography systems that produce chips quicker and with less power. Of course, implementing BAT technologies into semiconductor production will require significant infrastructure changes, so it remains to be seen how long it will take to come to fruition; the current EUV systems were developed over the course of decades.

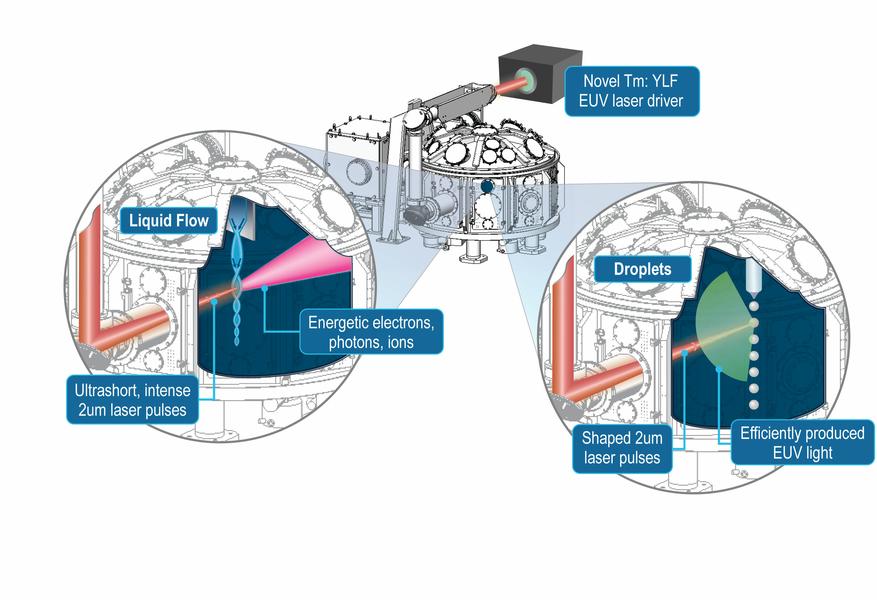

One of the peculiarities of extreme ultraviolet lithography is the extreme power consumption of the current-gen Low-NA EUV and next-gen High-NA EUV litho systems: the tools consume 1,170 and 1,400 kilowatts, respectively. EUV lithography tools consume such vast amounts of power because they rely on high-energy laser pulses to evaporate tiny tin droplets (at 500,000ºC) to form a plasma that emits 13.5-nanometer light. Generating these pulses at tens of thousands per second demands massive laser infrastructure and cooling systems. Generating and manipulating tin droplets also requires power.

In addition, vacuum requirements to prevent the absorption of EUV light by air add to the overall energy use. Finally, as advanced mirrors in EUV tools reflect only a fraction of EUV light, lasers must become more powerful to increase production capacity.

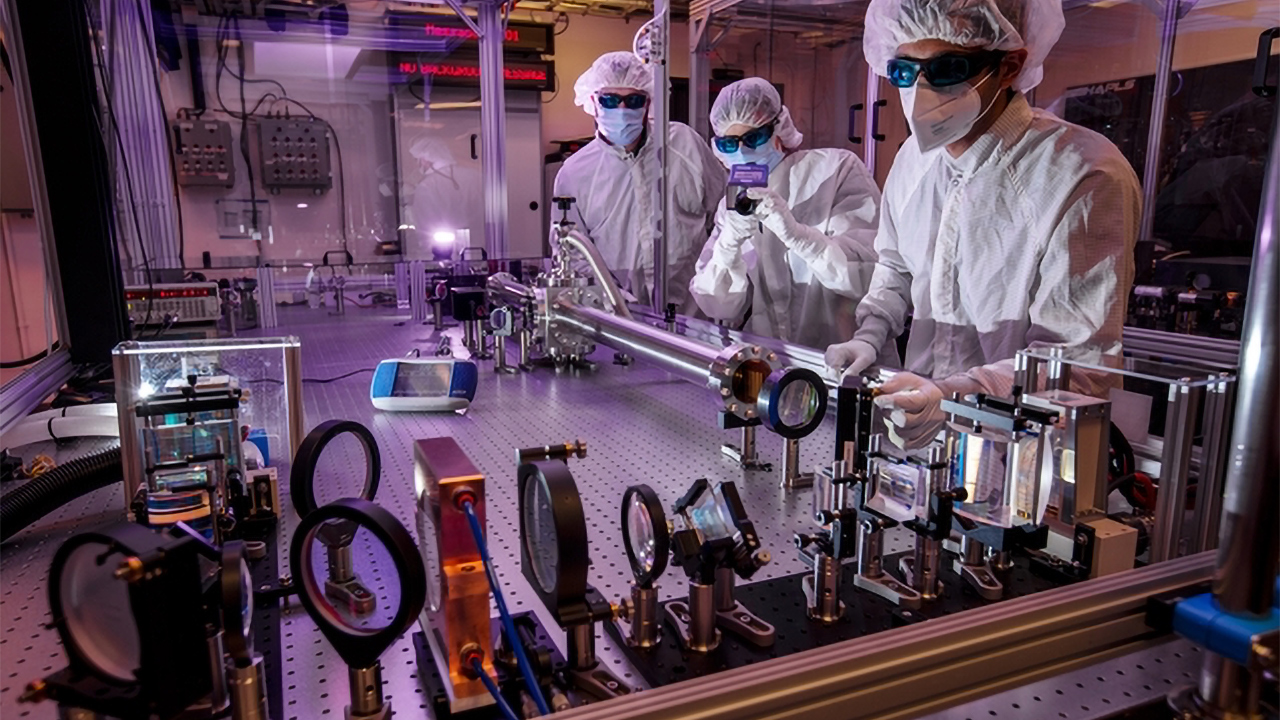

Lawrence Livermore’s team of researchers is testing whether technologies behind the BAT laser — built around thulium-doped yttrium lithium fluoride and capable of petawatt-class output — can raise the energy efficiency of current EUV tools. Unlike CO2 lasers that operate at a wavelength of about 10 microns, this system operates at around 2 microns, according to LLNL. This theoretically enables higher plasma-to-EUV conversion efficiency when interacting with tin droplets. Also, diode-pumped solid-state technology used in BAT systems can offer better overall electrical efficiency and heat management compared to gas-based CO2 setups.

Initially, the researchers aim to pair the compact, high-repetition-rate BAT laser (with different types of pulses) with systems that produce EUV light to test how a laser delivering joule-level pulses at a 2-micron wavelength interacts with tin drops.

“We have performed the theoretical plasma simulations and proof of concept laser demonstrations over the past five years that lay the foundations for this project,” said LLNL laser physicist Brendan Reagan. “Our work has already had quite an impact in the EUV lithography community, so now we’re excited to take this next step.”

Get Tom’s Hardware’s best news and in-depth reviews, straight to your inbox.

The power consumption of modern EUV tools and fabs has led industry analyst firmTechInsights to raise the alarmover the power consumption of semiconductor fabs. These fabs are projected to consume 54,000 gigawatts (GW) of power per year by 2030 — more than Singapore or Greece consume per annum. If next-gen Hyper-NA EUV lithography comes to market, the power consumption may be even higher. As such, we can expect the industry to continue to search for more power-efficient technologies to power future EUV machines.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.